Men’s Underwear Manufacturer

We are an underwear manufacturer with ten years of manufacturing experience. The following will introduce the relevant knowledge of underwear from both product and manufacturing aspects.

1. Products

1.1 Styles

1.1.1 Briefs

Briefs offer excellent front and side coverage. The waistband usually sits at the waist, ensuring stability and support. This style is compact, made from a variety of materials like cotton or blends, ensuring breathability and comfort. Suitable for everyday wear, sports activities, business, or formal occasions.

1.1.2 Boxers

Boxer shorts are known for their loose fit, offering maximum breathability and comfort. The leg coverage usually extends to the mid-thigh. Common materials include pure cotton and linen, enhancing breathability and moisture absorption. Suitable for wear at home, during sleep, and on long travels.

1.1.3 Trunks

Trunks are similar to boxer briefs but with shorter legs, providing a snugger fit. They often feature a seamless or minimal seam design to reduce friction and markings. The material frequently includes a blend of cotton with elastic fibers, such as spandex, to ensure better elasticity and shape retention. Ideal for casual activities, fitness, and long sitting periods.

1.2 Materials

1.2.1 Cotton

- Breathability: Cotton fabric is highly breathable, helping keep the skin dry and comfortable.

- Softness: Cotton is soft to the touch, ideal for sensitive skin, and provides a pleasant wearing experience.

- Ease of Cleaning: Cotton underwear is machine washable, convenient, and durable.

1.2.2 Modal

- Super Soft: Modal fiber is softer than cotton, offering supreme comfort.

- Moisture Wicking: More absorbent than cotton, suitable for sports and high-temperature conditions.

- Durability: Modal fiber is wrinkle-resistant, doesn’t shrink easily, and is durable

1.2.3 Spandex

- Stretchability: Excellent elasticity, providing superior fit and unrestricted movement.

- Shape Retention: Maintains its original shape even after long wear, resisting deformation.

- Support: Offers good support to body areas like the buttocks and thighs.

1.2.4 Bamboo

- Eco-Friendly: Bamboo fiber is a sustainable fabric with minimal environmental impact.

- Antibacterial and Odor Resistant: Natural antibacterial properties help reduce odors and keep freshness.

- Soft and Comfortable: Softer than cotton, providing extra comfort.

1.2.5 Polyester

- Durability: Highly durable, resistant to damage, ideal for frequent washing.

- Quick Drying: Dries quickly, suitable for outdoor activities and post-exercise wear.

- Shape Retaining: Resists wrinkles, easy to maintain, suitable for long-wearing periods.

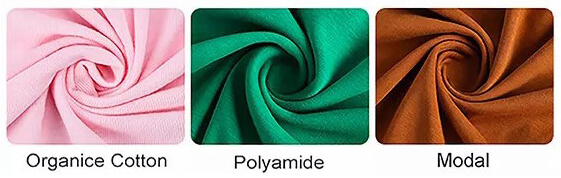

1.3 Fabrics

Choosing the right fabric is crucial as it directly impacts the product’s comfort, durability, and market appeal.

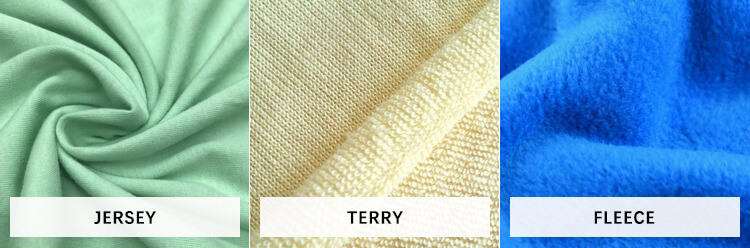

1.3.1 Jersey

Jersey is typically made from cotton or a cotton blend, offering good stretch and softness. Its smooth, close-fitting characteristics make it an ideal choice for underwear.

1.3.2 Terry

Terry fabric features looped or twisted piles and is usually made from cotton. It’s soft to the touch and has strong water absorption.

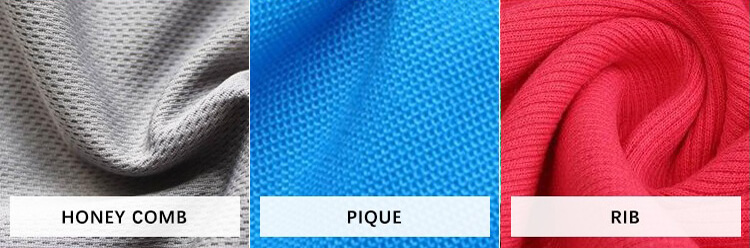

1.3.3 Honey Comb

Honey comb fabric has a structure similar to a honeycomb, providing excellent breathability and moisture absorption, commonly used in sportswear.

1.3.4 Pique

Pique fabric usually has a raised weave and is often seen in polo shirts. Its structure allows for air circulation, helping to keep it dry.

1.3.5 Rib

Rib fabric features distinct vertical ribs and great stretchability, suitable for underwear that requires a snug fit.

1.4 Technology

The cutting techniques used in underwear production are crucial not only for comfort and functionality but also affect the overall texture and durability of the product.

1.4.1 3D Ergonomic Cut

3D ergonomic cut is a tailoring technique that mimics the male body structure, ensuring a perfect fit of the underwear on the body through precise cutting and sewing techniques. This method particularly focuses on designing ample space in the crotch and buttocks areas to provide additional comfort and freedom of movement.

1.4.2 Seamless Sides

The seamless sides design involves a special production technique that reduces or eliminates the side seams of the underwear. This design helps to minimize friction and irritation while wearing, making it especially suitable for consumers with sensitive skin.

1.4.3 Reinforced Crotch

Reinforcing the crotch involves adding an extra layer of fabric or using more durable stitching at crucial areas of the underwear to enhance its structure. This technique helps to increase the durability of the underwear, particularly in high-intensity activities.

1.4.4 Elastic Waistband

The design of the elastic waistband includes choosing high-quality elastic materials and the appropriate width of the waistband to ensure the underwear comfortably stays in place around the waist without causing compression or slipping. Additionally, the design of the waistband often features anti-wrinkle and anti-stretch properties to maintain the shape and longevity of the product.

1.4.5 Functional Partitioning

Functional partitioning involves dividing the underwear into several zones based on different bodily needs and using various fabrics and technologies to meet these needs. For example, the leg area might use a more breathable fabric, while the crotch area might use a softer or antibacterial fabric.

2. Manufacturing

2.1 Sampling

Before mass production begins, we create a prototype. This initial stage involves reviewing the design and specifications to ensure practical feasibility. Sample making includes translating the design, selecting fabrics and accessories, and performing initial manual sewing. Choosing the right fabric is crucial as it directly affects the comfort, breathability, and durability of the underwear. Common fabric choices include cotton for its softness and breathability, modal for its stretch and wear resistance, nylon, and various blends.

2.2 Cutting

We use advanced cutting equipment to precisely cut the fabric according to design specifications. Accuracy in cutting is crucial as it affects the overall appearance and fit of the finished garment.

2.2.1 Computerized Cutting Machines

These machines cut fabric accurately according to preset dimensions and shapes, ensuring uniformity and precision. They are typically used in mass production to enhance efficiency and material utilization.

2.2.2 Laser Cutting Machines

Ideal for high-precision cutting, especially for complex or fine designs. This equipment reduces fabric edge fraying, enhancing the neatness and aesthetics of the final product.

2.3 Sewing

The cut fabric pieces are sewn together to form the underwear. This step requires high precision in sewing techniques and quality control.

2.3.1 Sewing Machines

The primary tools for assembling underwear parts. There are various types of sewing machines available, including single-needle flat seam machines, double-needle sewing machines, and overlock machines, each serving specific purposes. For instance, overlock machines are particularly suitable for constructing underwear leg openings and waistbands due to their ability to provide strong elastic seams.

2.3.2 Automated Waistband Machines

These specialize in sewing the waistbands of underwear, automating the attachment and stitching process. These machines ensure the uniformity and durability of waistbands, essential for high-quality underwear production.

2.4 Ironing

Before ironing, ensure all underwear pieces have been washed and dried to remove moisture and any residual substances. The ironing temperature should vary based on the material, with higher temperatures for cotton and blends, and lower for synthetics like modal or viscose to avoid damage.

2.5 Quality Inspection

After sewing, each piece undergoes rigorous quality inspection to ensure there are no defects. This includes checking for neat stitching, accurate sizing, fabric flaws, and the overall appearance of the product.

2.5.1 Fabric Quality

- Inspect the fabric for any defects such as stains, holes, or weaving errors.

- Ensure the fabric color is uniform, without fading or discrepancies.

- Verify that the fabric’s texture and elasticity meet the product specifications.

2.5.2 Size and Fit

- Check that the underwear’s size aligns with the design specifications, including waist and leg measurements.

- Ensure the cut is correct and that the proportions of the underwear are harmonious.

- Conduct fit tests to verify comfort and suitability.

2.5.3 Sewing and Construction

- Inspect the stitching for neatness and uniformity, ensuring there are no loose threads or slackness.

- Ensure all seams and junctions are robust, with no fraying or cracks.

- Check for any signs of excessive stretching or damage at the elastic bands and seam areas.

2.5.4 Durability Testing

- Perform washing tests to check the underwear’s durability and color stability after multiple washes.

- Test the underwear for wrinkle resistance and shape retention.

- Evaluate how the fabric and seams perform under continuous use.

2.5.5 Comfort Inspection

- Inspect the interior of the underwear for any rough seams or tags that could cause discomfort when worn.

- Verify the fabric’s breathability and moisture-wicking properties to ensure comfort while worn.

- Assess whether the overall design of the underwear conforms to ergonomic principles.

2.5.6 Information Checking

- Ensure the underwear’s packaging meets brand standards and that the packaging materials are undamaged.

- Check the accuracy of label information on the packaging, including size, washing instructions, and material composition.

2.6 Packaging

Products that pass quality control are cleaned, ironed, folded, and finally packaged. Packaging is designed not just to protect the product but also to appeal to consumers, incorporating brand tags, instructions, and appropriate packaging materials.

We hope this detailed overview helps you understand the critical steps involved in manufacturing men’s underwear. If you have any questions or need further information, feel free to reach out.

3. Problem and Solution

3.1 Fabric Shrinkage and Deformation

- Problem: During washing and wearing, fabrics may shrink or become misshapen, affecting the underwear’s comfort and durability.

- Solution: Opt for pre-shrunk fabrics or perform shrinkage tests before production. Use blends with stable fibers, such as a certain percentage of synthetic fibers, to enhance fabric stability.

3.2 Loose Stitching

- Problem: Stitching may become loose due to poor sewing quality or substandard thread.

- Solution: Use high-quality sewing thread and ensure the sewing machines are properly set. Regularly maintain and calibrate sewing machines to guarantee stitch uniformity and tightness.

3.3 Inconsistent Sizing

- Problem: Inconsistencies in sizing during production can lead to uneven product quality.

- Solution: Strictly control the size tolerances during cutting and sewing. Use automated cutting machines and templates to standardize sizing across all products.

3.4 Uneven Color or Fading

- Problem: Fabric colors may become uneven or fade after production or washing.

- Solution: Use high-quality dyes and fixatives and tightly control the dyeing process parameters. Conduct thorough colorfastness testing to ensure color stability.

3.5 Pilling

- Problem: Some fabrics may pill after prolonged wear and friction.

- Solution: Choose low-pilling fabrics, such as long-fiber cotton or treated synthetic fibers. Include anti-pilling treatment during the production process.

3.6 Uncomfortable Seam Placement

- Problem: Improperly handled seam placements can cause discomfort to the wearer.

- Solution: Consider seam placement and type during design, using flat-seam techniques to minimize friction. Employ ultra-soft thread and meticulous sewing methods.

3.7 Elastic Band Loosening

- Problem: The elastic bands in underwear may loosen after wear and washing.

- Solution: Select high-quality elastic materials and the correct width for the elastic bands. Ensure that the elastic bands are securely sewn and evenly distributed.